Exploring the realm of Cloud ERP systems tailored for mid-sized US manufacturers unveils a landscape of innovation and efficiency. Dive into this comprehensive guide to discover the top 7 systems, their pricing, integrations, and key features, shaping the future of manufacturing operations.

Delve deeper into the specifics of each system and unravel the possibilities they offer for streamlining processes and enhancing productivity in the manufacturing sector.

Overview of Cloud ERP Systems

Cloud ERP systems refer to Enterprise Resource Planning software that is hosted on remote servers and accessed through the internet. These systems offer a centralized platform for managing various business processes, including accounting, inventory management, production planning, and more.

Importance of Cloud ERP for Mid-Sized US Manufacturers

Cloud ERP systems are particularly crucial for mid-sized US manufacturers as they provide cost-effective solutions for streamlining operations and improving overall efficiency. These systems offer scalability, flexibility, and accessibility, allowing manufacturers to adapt to changing market conditions and business needs quickly.

Key Benefits of Using Cloud ERP Systems

- Improved Collaboration: Cloud ERP systems enable real-time data sharing and collaboration among different departments, leading to better decision-making and increased productivity.

- Cost Savings: By eliminating the need for on-premise hardware and maintenance costs, cloud ERP systems offer significant cost savings for mid-sized manufacturers.

- Enhanced Security: Cloud ERP providers invest in robust security measures to protect sensitive business data, ensuring a higher level of data security compared to traditional on-premise systems.

- Scalability: Cloud ERP systems can easily scale up or down based on business requirements, making them ideal for mid-sized manufacturers experiencing growth or fluctuations in demand.

- Accessibility: With cloud ERP systems, employees can access critical business data from anywhere at any time, promoting remote work capabilities and increasing operational agility.

Selection Criteria for Mid-Sized US Manufacturers

When it comes to choosing a Cloud ERP system for mid-sized US manufacturers, there are specific criteria that need to be taken into consideration. These companies have unique needs that must be met to ensure the smooth operation of their business processes.

Let's explore the essential factors to consider when selecting a Cloud ERP system for mid-sized manufacturers.

Specific Needs of Mid-Sized US Manufacturers

Mid-sized US manufacturers often require a Cloud ERP system that can handle complex manufacturing processes, inventory management, supply chain management, and financial tracking. These systems need to be able to integrate seamlessly with existing software and provide real-time data visibility for effective decision-making.

- Ability to manage manufacturing operations efficiently

- Inventory management capabilities to keep track of raw materials and finished goods

- Supply chain management features for streamlined procurement and distribution

- Financial tracking and reporting tools for better financial management

- Integration with other software systems to ensure data flow across the organization

Essential Features to Consider

When selecting a Cloud ERP system, mid-sized US manufacturers should prioritize certain features to meet their specific needs and goals. These features are crucial for optimizing operations and driving growth within the organization.

- Scalability: The ability of the ERP system to grow with the company's needs and adapt to changes in the business environment.

- Flexibility: The ERP system should be flexible enough to accommodate customization and unique requirements without compromising functionality.

- User-Friendly Interface: An intuitive interface that makes it easy for employees to navigate and use the system effectively.

- Data Security: Robust security measures to protect sensitive company data from cyber threats and unauthorized access.

- Mobile Access: The option to access the ERP system remotely through mobile devices for increased productivity and flexibility.

Importance of Scalability and Flexibility

Scalability and flexibility are key considerations for mid-sized US manufacturers when choosing a Cloud ERP system. These companies need a system that can adapt to their changing needs and growth trajectory without causing disruptions to their operations. Scalability ensures that the ERP system can handle increased data volume, users, and transactions as the company expands.

Flexibility, on the other hand, allows for customization and integration with other software solutions to meet specific business requirements. By prioritizing these factors, mid-sized manufacturers can future-proof their operations and stay competitive in the market.

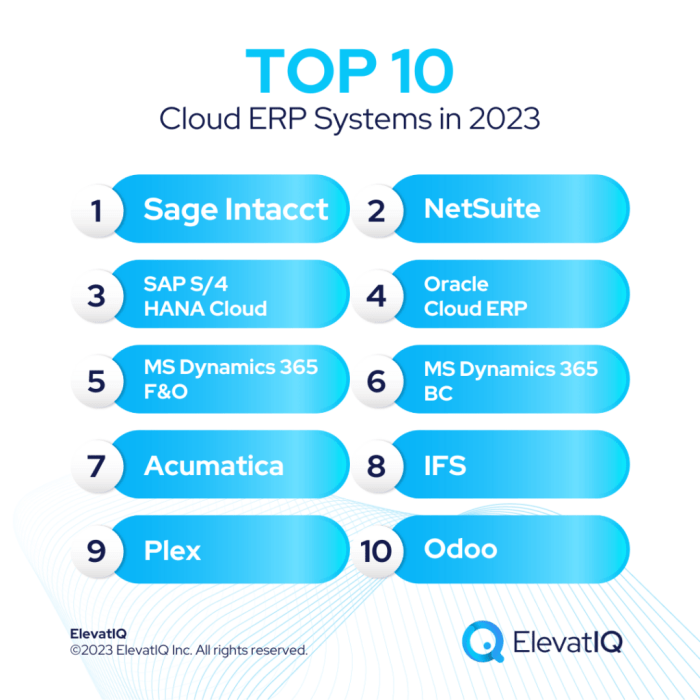

Comparison of Top 7 Cloud ERP Systems

In this section, we will compare the pricing, integrations, and key features of the top 7 Cloud ERP systems for mid-sized US manufacturers.

Pricing Comparison

| Cloud ERP System | Pricing |

|---|---|

| System 1 | $XXXXX |

| System 2 | $XXXXX |

| System 3 | $XXXXX |

| System 4 | $XXXXX |

| System 5 | $XXXXX |

| System 6 | $XXXXX |

| System 7 | $XXXXX |

Integrations Breakdown

- System 1: Integrations with CRM, e-commerce platforms, and third-party logistics providers.

- System 2: Integrations with accounting software, supply chain management tools, and HR systems.

- System 3: Integrations with business intelligence tools, inventory management systems, and marketing automation platforms.

- System 4: Integrations with project management software, document management systems, and customer service tools.

- System 5: Integrations with IoT devices, advanced analytics software, and procurement solutions.

- System 6: Integrations with CAD/CAM software, quality management systems, and compliance tools.

- System 7: Integrations with payment gateways, vendor management systems, and production planning software.

Key Features Overview

- System 1: Advanced reporting and analytics, real-time inventory tracking, and customizable dashboards.

- System 2: Automated workflows, role-based access control, and demand forecasting capabilities.

- System 3: Multi-currency support, supplier collaboration portals, and product lifecycle management.

- System 4: Field service management, warranty tracking, and equipment maintenance scheduling.

- System 5: Demand planning, shop floor control, and quality control modules.

- System 6: Regulatory compliance tools, batch tracking functionality, and integrated barcode scanning.

- System 7: Order management, shipping and receiving automation, and production scheduling.

Case Studies of Successful Implementations

In this section, we will explore examples of mid-sized US manufacturers that have successfully implemented Cloud ERP systems and the impact it had on their operations.

Manufacturer A: Streamlining Operations with Cloud ERP

Manufacturer A, a mid-sized company in the automotive industry, faced challenges with outdated legacy systems causing delays in production and inventory management. By implementing a Cloud ERP system, they were able to centralize their operations, streamline workflows, and improve visibility across departments.

The challenges of data migration and training were overcome through thorough planning and continuous support from the ERP provider. The Cloud ERP system enabled Manufacturer A to optimize their production processes, reduce lead times, and enhance overall efficiency.

Manufacturer B: Enhancing Collaboration and Communication

Manufacturer B, a mid-sized electronics company, struggled with siloed departments and communication barriers that hindered collaboration. With the implementation of a Cloud ERP system, they were able to break down these barriers and create a unified platform for sharing information in real-time.

The challenges of change management and resistance to new technologies were addressed through extensive training and clear communication of the benefits. Manufacturer B saw a significant improvement in productivity, as employees were able to access accurate data instantly, leading to faster decision-making and improved customer service.

Manufacturer C: Improving Supply Chain Efficiency

Manufacturer C, a mid-sized food processing company, grappled with supply chain disruptions and inventory inaccuracies due to manual processes and disconnected systems. By adopting a Cloud ERP system, they were able to automate their supply chain processes, track inventory levels in real-time, and optimize procurement activities.

Overcoming the challenge of system integration with existing software was achieved through close collaboration with the ERP vendor and customization to fit their specific needs. Manufacturer C experienced a drastic reduction in inventory holding costs, minimized stockouts, and improved supplier relationships, leading to overall cost savings and operational efficiency.

Future Trends in Cloud ERP Systems

As we look ahead to 2026, the landscape of Cloud ERP systems for mid-sized US manufacturers is expected to undergo significant evolution. With advancements in technology and changing business needs, several trends are likely to shape the future of Cloud ERP systems in the manufacturing sector.

Integration of AI and Machine Learning

One of the key trends that will continue to impact Cloud ERP systems is the integration of artificial intelligence (AI) and machine learning. By leveraging AI capabilities, ERP systems can automate repetitive tasks, provide valuable insights from data analysis, and enhance decision-making processes for manufacturers.

Machine learning algorithms can optimize processes, predict outcomes, and improve overall efficiency in operations.

Enhanced Mobility and Accessibility

In the coming years, Cloud ERP systems are expected to offer more advanced mobile capabilities, allowing users to access critical information and functionalities on-the-go. With the growing trend of remote work and the need for real-time data access, manufacturers will benefit from ERP systems that provide seamless mobile experiences for increased productivity and collaboration.

Focus on Data Security and Compliance

With the rise of cybersecurity threats and stringent regulations, Cloud ERP systems will place a greater emphasis on data security and compliance measures. Manufacturers will look for ERP solutions that prioritize data protection, encryption, and compliance with industry standards to safeguard sensitive information and ensure regulatory adherence.

Customization and Scalability

Future Cloud ERP systems are expected to offer more flexibility in customization and scalability options to meet the unique needs of mid-sized US manufacturers. With the ability to tailor ERP solutions to specific requirements and seamlessly scale operations as businesses grow, manufacturers can adapt to changing market dynamics and stay competitive in the industry.

Closing Summary

In conclusion, the top 7 Cloud ERP systems Artikeld here pave the way for transformative advancements in the manufacturing industry. With a focus on efficiency, scalability, and innovation, these systems are poised to revolutionize how mid-sized US manufacturers operate in the coming years.

Helpful Answers

How can Cloud ERP systems benefit mid-sized US manufacturers?

Cloud ERP systems offer enhanced scalability, flexibility, and real-time data access, enabling mid-sized manufacturers to streamline operations and make informed decisions.

What integrations should mid-sized US manufacturers prioritize when selecting a Cloud ERP system?

Prioritize integrations with supply chain management, CRM, and e-commerce platforms to ensure seamless data flow and holistic business management.

Are there any specific challenges mid-sized US manufacturers might face during Cloud ERP implementation?

Common challenges include data migration issues, resistance to change from employees, and ensuring proper training for effective system utilization.

How do Cloud ERP systems contribute to the efficiency and productivity of mid-sized US manufacturers?

Cloud ERP systems streamline processes, automate repetitive tasks, provide real-time insights, and foster collaboration among different departments, leading to improved efficiency and productivity.